For commercial and residential solar installers seeking unmatched efficiency and reliability, Clenergy stands as a global innovator in solar mounting innovation. Their commitment to engineering excellence is embodied in the PV-ezRack product line, particularly the advanced SolarRoof™ Pro 2.0. This system redefines installation speed and versatility, setting a new benchmark for solar roof racking systems.

Hassle-Free, Time-Saving Installation

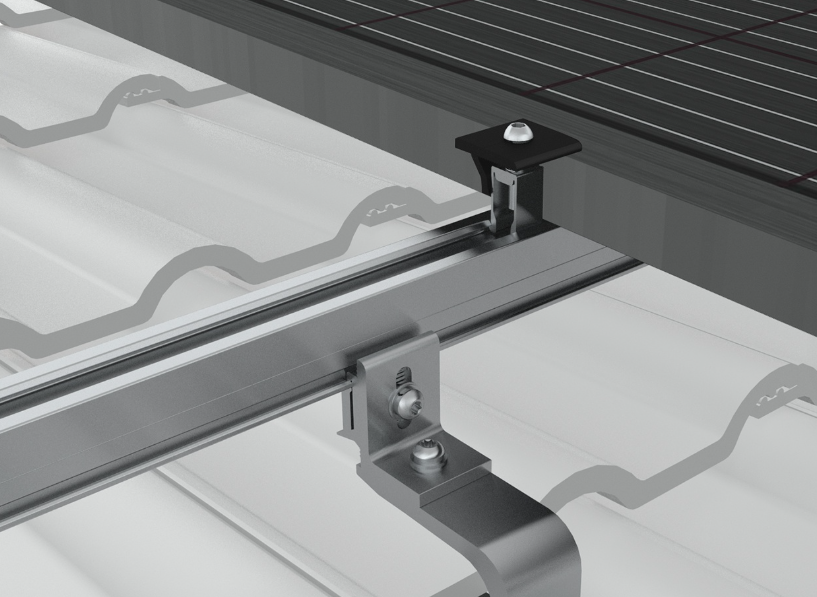

The SolarRoof™ Pro 2.0 is engineered to drastically reduce labor time and complexity. A cornerstone of the Clenergy PV-ezRack philosophy is simplicity. The system features a revolutionary “one-tool” installation process for the entire roof hook assembly, minimizing tool changes and technician training time. High-quality, durable hooks and rails, secured with ETA-certified screws, guarantee a robust and safe solar roof racking system installation, protecting both the array and the building structure. This focus on streamlined workflows makes the Clenergy PV-ezRack solution a top choice for high-volume contractors.

Ultimate Layout Flexibility with One SKU

Maximize project design freedom without inventory headaches. A key innovation of the SolarRoof™ Pro 2.0 within the Clenergy PV-ezRack range is its universal compatibility. The same kit and single SKU seamlessly adapts to both landscape and portrait panel orientations. This eliminates the need for multiple parts, simplifies procurement, reduces warehouse complexity, and prevents costly installation delays due to incorrect components. This unparalleled flexibility is a defining feature of modern solar roof racking systems designed for diverse project requirements.

Conclusion

Clenergy‘s PV-ezRack SolarRoof™ Pro 2.0 delivers tangible benefits: faster installs, reduced labor costs, minimized inventory, and uncompromised safety. It exemplifies the evolution of efficient solar roof racking systems. By choosing Clenergy PV-ezRack, installers invest in a system built for speed, adaptability, and long-term performance, ensuring projects are completed on time and within budget while meeting the highest quality standards. Experience the future of rooftop solar mounting with Clenergy.