When operating a CNC machine, selecting the appropriate CNC drilling machine tool is essential for achieving high-precision results. Whether for wood, metal, or plastic applications, the CNC drilling machine performs various drilling, milling, and grooving tasks, making the choice of drill crucial to the final output. High-quality drills ensure clean, accurate holes and grooves, reducing the chances of errors and maximizing the lifespan of the CNC drilling machine.

Factors to Consider When Selecting Drills for CNC Machines

Choosing the right drill for your CNC machine involves several factors. One of the primary considerations is the material compatibility with the CNC machine. Drills need to be suited for different materials, whether it is hard metals, soft woods, or composites. Moreover, the size and geometry of the drill bit are significant. For instance, when working with larger panels, you may need drills that can handle multi-sided drilling, like the HUAHUA CNC models that feature five-tool magazines for diverse machining needs. Additionally, the design of the drilling head should accommodate the necessary precision and speed for the job.

Why HUAHUA CNC Drilling Machines Stand Out

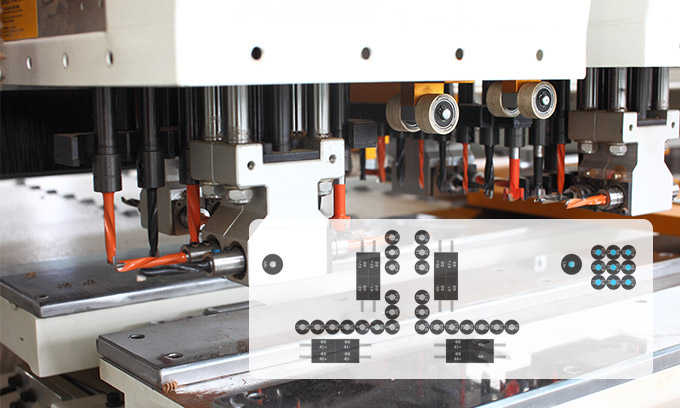

HUAHUA CNC has made significant advancements in the realm of CNC drilling machines, offering unparalleled performance. The HUAHUA CNC systems, such as the SKH-612HST, come with double precision drilling heads, ensuring that each drilling operation is executed with pinpoint accuracy. These independently developed drilling heads are manufactured to international standards, offering exceptional durability and reliability. With these features, operators can achieve up to 6-side drilling and 2-side grooving in one pass, a feature that sets HUAHUA CNC systems apart from standard machines.

Moreover, the ability to handle both vertical and horizontal drilling with up to 12 top and 8 horizontal drilling positions on each side provides flexibility for varied tasks. These features, combined with a powerful 3.5kw spindle, enhance the performance and efficiency of the CNC drilling machine.

Conclusion

Choosing the correct drill for your CNC machine can have a major impact on the efficiency and quality of your work. It is crucial to consider factors such as material type, drill size, and machine capabilities. Systems like the HUAHUA CNC drilling machine, with its high precision and durable features, offer solutions for complex tasks, reducing the time and effort needed to complete projects. With the right CNC drilling machine and drill bit combination, businesses can achieve superior quality while maintaining high productivity and cost-effectiveness.