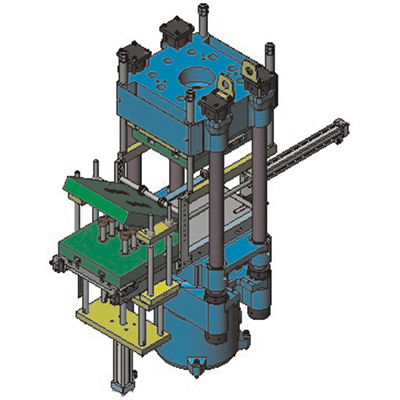

For decades, Dekuma has specialized in the development and production of advanced rubber injection molding equipment. Their technology supports demanding industries such as automotive, electrical power, engineering vehicles, agricultural machinery, and defense applications. By focusing on the design of core machine components and strict material selection, they provide customers with high levels of stability and reliability. In niche sectors like rubber track production and insulator manufacturing, Dekuma offers a customized injection molding machine that helps customers improve efficiency while meeting unique production requirements.

Advantages of a custom injection molding machine

Different industries often face distinct technical challenges when processing rubber parts. A custom injection molding machine allows manufacturers to adapt to specific shapes, sizes, and performance standards. Dekuma addresses these needs by delivering equipment tailored to industry applications. For example, in the production of high-durability rubber tracks for agricultural machinery, the machines ensure consistent molding quality that extends the lifespan of final products. Similarly, for electrical insulators, the precision control provided by their systems contributes to safer and more stable performance under demanding conditions.

Industry-focused innovation

Rather than offering one-size-fits-all equipment, Dekuma invests in continuous research to refine solutions for specialized markets. Their customized injection molding machine options are designed in-house by an experienced technical team, ensuring that every feature aligns with customer goals. By integrating advanced control systems, these machines maintain uniformity, reduce waste, and meet strict technical requirements. Customers benefit not only from reliable equipment but also from professional support that shortens setup time and enhances productivity.

Conclusion

Through consistent innovation and commitment to industry-specific needs, Dekuma has established itself as a reliable partner for businesses seeking tailored rubber processing equipment. Their ability to deliver both a custom injection molding machine and a customized injection molding machine positions them as a valuable choice for companies requiring precise solutions in specialized fields such as insulator production and rubber track manufacturing. With this approach, they continue to create long-term value for customers worldwide.